Development of automated capsule production for hospital pharmacies

2 October 2024

M. Decuyper, V. Hay, A. Melaye, L. Pacqueu, M. Vasseur, M. Bouchfaa, P. OdouCentre Hospitalier Universitaire de Lille, France

Introduction

The increase in demand, the use of preparations during drug shortage and the possibility of increasing batch sizes under the new Good Preparation Practices for Compounding are three factors that are driving the automation of our preparation processes. Against this backdrop, we have invested in an automatic capsule filler (INCAP SE, Bonapace). Initial work has been carried out using excipients used for manual preparations, revealing flow difficulties. The aim of this work is to test the excipients used in the pharmaceutical industry and to validate the most suitable for the capsule filler.

Materials and methods

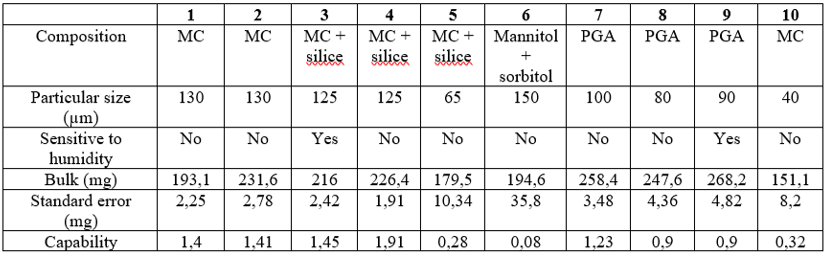

Ten excipients specific to automated production from the pharmaceutical industry containing microcrystalline cellulose (MC), microcrystalline cellulose silicified, mannitol with sorbitol or pregelatinised amidon (PGA) were selected to determine the excipient offering the best formulation in the capsule filler. These excipients were chosen on the basis of particle size, density, moisture sensitivity and the presence of a flow agent. For each excipient, 300 g of powder were weighed and 300 size 2 capsules were produced using the capsule filler. The parameters studied were powder flow in the hopper, capsule filler fouling and capsule mass, enabling the process capability index to be calculated using R software (qcc library).

Results

Excipients (2), (3) and (4) obtained capability indices greater than 1.33. The flow within the hopper and the clogging of the PLC of excipient (2) is not satisfactory compared to (3) and (4). Excipient (4) offers better process control (capability = 1.91).

Conclusion and discussion

The formulation containing microcrystalline cellulose with moisture-insensitive silica appears to be the optimal excipient for production with the automatic capsule filing machine. This work is a first step towards the development of other capsule formulations using the capsule filler, taking into account the characteristics of each active ingredient.